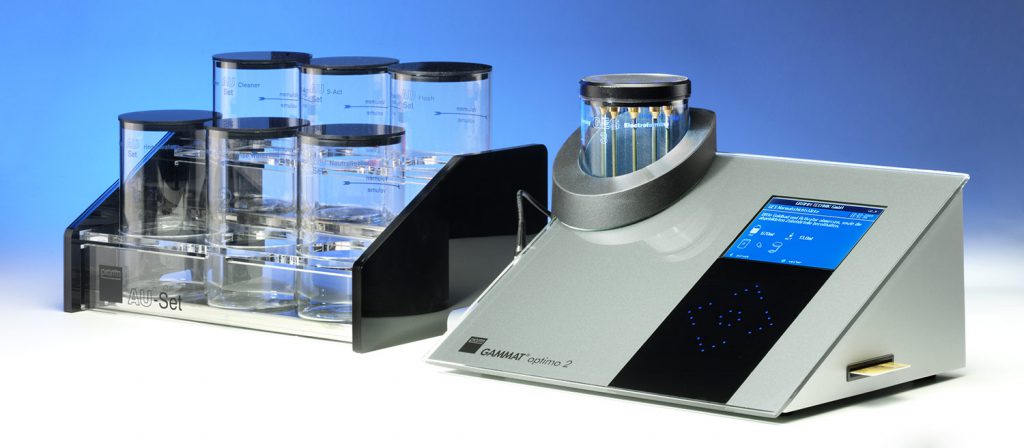

One for all… electroforming,

hard gold plating, and friction renewal

With the GAMMAT® optimo2, Gramm relies on the classical, well-tried advantages of the electroforming technique and combines this with state-of-the-art unit technology. Thus, one compact unit is sufficient to cover all electroforming indications and hard gold plating cases of model casting frameworks and friction renewal of worn telescopic dentures, tapered crowns and bar-retained restorations out of non-precious or high-noble alloys – with the advantage to adjust the layer thickness. This unit distinguishes by its easy operation via menu-guided display indications and an extremely high process safety. Thus, the user is offered utmost benefit at low investment and operating costs.

Over 30 years experience

When the GAMMAT 12, the first electroforming unit that worked fully automatically, was launched on the market in 1989, this meant nothing else but the breakthrough of this accurate and biocompatible technique. In the past 29 years, the dental technology and also the unit development have been in a state of flux. But one constant has persisted. The name of the original is still the same: GAMMAT®.

Gramm is expert and leader of the world market in electroforming technology. The Gramm electroforming technique means more – more advantages for the dental technician as well as for the patient and for the dentist.

More comfort

- Very easy handling since all steps are indicated on the display

- Power and time settings are made automatically

- Automatic calculation of the amount of gold solution required

More quality

- Homogeneous gold layer with a wall thickness of approx. 180 or 220 µm

- Exact fit

- Certified gold solution (CE 0483), no arsenic or other toxic substances added, cytotoxity test passed

More efficiency

- Reasonable investment costs

- Integrated recycling programme to extract residual gold out of the gold solution